How to configure tunable DWDM-XFP-C on ASR9010

Currently we have a CRS-3 router connected to a 7609 router throu...

What you need to know about 100G

What you need to know about 100G Transporting data was up to 1...

Compatibility guide for Fiber Optic Modules

Compatiblebrand Model TinoutProduct type Product descr...

SFP Definition from Tinout

(Small Form-factor Pluggable) A small transceiver that plugs into the SFP port of a network switch and connects to Fibre Channel and Gigabit Ethernet (GbE) optical fiber cables at the other end. Superseding the GBIC transceiver, SFP modules are also called "mini-GBIC" due to their smaller size. By choosing the appropriate SFP module, the same electrical port on the switch can connect to fibers of different types (multimode or singlemode) and different wavelengths. If the fiber is upgraded,

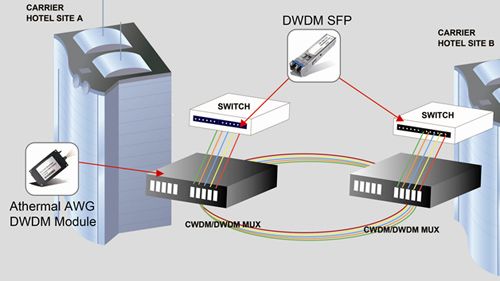

WDM-SYSTMES

Early fiber optic transmission systems put information onto strands of glass through simple pulses of light. A light was flashed on and off to represent the ¡°ones¡± and ¡°zeros¡± of digital information. The actual light could be of almost any wavelength (also known as color or frequency) from roughly 670nm to 1550nm.

During the 1980s, fiber optic data communications modems used low-cost LEDs to put near-infrared pulses onto low-cost fiber. As the need for information increased, the need for bandwidth also increased. Early SONET systems used 1310nm lasers to deliver 155 Mb/s data streams over very long distances. But this capacity was quickly exhausted. Advances in optoelectronic components allowed design of systems that simultaneously transmitted multiple wavelengths of light over a single fiber. Multiple high-bit rate data streams of 2.5 Gb/s, 10 Gb/s and, more recently, 40 Gb/s and 100Gb/s could be multiplexed through divisions of several wavelengths. And so was born Wavelength Division Multiplexing (WDM).

CWDM - Coarse Wavelength Division Multiplexing. WDM systems with fewer than eight active wavelengths per fiber.

DWDM - Dense Wavelength Division Multiplexing. WDM systems with more than eight active wavelengths per fiber.

Types of WDM

Currently, there are two types of WDM in existence today: Coarse WDM (CWDM) and Dense

WDM (DWDM). Backwards as it may seem, DWDM came well before CWDM, which appeared only after a booming telecommunications market drove prices to affordable lows. Whereas CWDM breaks the spectrum into big chunks, DWDM dices it finely. DWDM fits 40-plus channels into the same frequency range used for two CWDM channels.

CWDM is defined by wavelengths. DWDM is defined in terms of frequencies. DWDM¡¯s tighter wavelength spacing fit more channels onto a single fiber, but cost more to implement and operate.

Distinctive CWDM differences

CWDM can¡ªin principle¡ªmatch the basic capabilities of DWDM but at lower capacity and lower cost. CWDM enables carriers to respond flexibly to diverse customer needs in metropolitan regions where fiber may be at a premium. However, it¡¯s not really in competition with DWDM as both fulfill distinct roles that largely depend upon carrier-specific circumstances and requirements anyway. The point and purpose of CWDM is short-range communications. It uses wide-range frequencies and spreads wavelengths far apart from each other. Standardized channel spacing permits room for wavelength drift as lasers heat up and cool down during operation. By design, CWDM equipment is compact and cost-effective as compared to DWDM designs.

Distinctive DWDM differences

DWDM is designed for long-haul transmission where wavelengths are packed tightly together. Vendors have found various techniques for cramming 32, 64, or 128 wavelengths into a fiber. When boosted by Erbium Doped-Fiber Amplifiers (EDFAs)¡ªa sort of performance enhancer for high-speed communications¡ªthese systems can work over thousands of kilometers. Densely packed channels aren¡¯t without their limitations. First, high-precision filters are required to peel away one specific wavelength without interfering with neighboring wavelengths. Those don¡¯t come cheap. Second, precision lasers must keep channels exactly on target. That nearly always means such lasers must operate at a constant temperature. High-precision, high-stability lasers are expensive, as are related cooling systems.